|

Shanghai Mekind Industrial Co., Limited

|

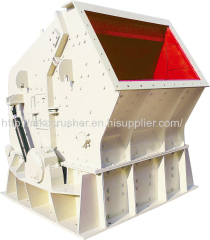

8 pcs hammer plates of impact crushing unit for quarry

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Big crushing ratio: 10:1

2.Big feed opening size: 500mm

3.The blow bar with high chrome

4.Easy maintenance and reliable operation

As the secondary crushing equipment, impact crusher is more suitable for crushing all kinds of stones or minerals with compression strength not more than 320Mpa. It is widely used in highway, railway, airport, reservoir areas. It has high capacity, high performance, high crushing ratio, low cubic shape and pin shape. Impact crusher is equipped with one rotor on which there are four to eight hammer plates. When one sides of hammer plate is abraded, the other side can be used again. This kind of impact machine has the advantages of simple structure, high crushing ratio, low energy consumption, high output, light weight, cubical shape of final products . It has been widely used in industries such as chemical, cement, building materials, ceramics, refractory materials, such as the use of a variety of moderate hardness with finely crushed glass materials: limestone, clinker, slag, coke, coal, etc. Compared with hammer crusher, impact crusher has a larger reduction ratio, higher impact energy which can make full use of the entire rotor, more reliable working performance.Thus, impact crusher are warmly welcomed by users.

As impact crushing becomes more prevalent in the production some harder types of aggregates, it is natural for those not completely familiar with the process, or recent improvements in technology, to wonder why impactors are being specified in situations previously often considered uneconomical or, at best, marginally feasible for this type of equipment. This simple answer is that the rules for determining the economic feasibility of utilizing impact systems have changed over the last few years, and are continuing to change at an accelerating pace.

Before talk about the new economics of impact crusher's usage, it maybe well to briefly state the advantages of the impact crusher in the production of aggregate. Low invest cost has always been the first advantage of this equipment. For a given application this first cost may well be only a quarter as much as for compression type crusher installation. Second, a bigger reduction ratio can be achieved. Many installations are now producing specification stone from run-of-quarry feed in a single pass through a primary impact crusher. Third, impact units are capable of accepting larger feed sizes, with maximum feeding size up to 500mm. This larger feed size capability reduces material hang-up in the feed hopper and the need for secondary blasting or reducing oversize rock in the quarry before transporting it to the primary crusher. And fourth, impact crushing can produce a higher quality products which are in cubical shape and without the slivers or slabs, thus making it easier for quarry plant operators to meet the stringent specifications laid down by many customers. That is the biggest advantage compared to other crushers.

Single or double toggle jaw crusher | 6:1 |

Gyratory crusher | 8:1 |

Standard head cone crusher | 7:1 |

Fine (short) head cone crusher | 5:1 |

Hammer mill or impact crusher | Up to 10:1 |

From the above table, we can see that impact crusher offers the highest reduction ratio of all crushers.

Each of above advantages leads automatically to certain economic advantages, as well as to some recognized disadvantages. However, some of the potential economics have not totally exploited. Now it is well known among all producers how some of the old disadvantages have been overcome in some of the newer units and systems now appearing in newer quarries.

In brief, compression is the forcing of surfaces toward one another to crush the material caught between them. Impact crushing can be of two variations---gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate.