|

Shanghai Mekind Industrial Co., Limited

|

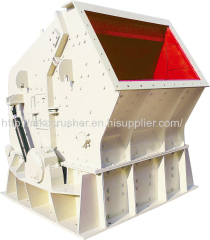

PF Impact Crushing Equipment with Final Products in Cubical Shape

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Models available: PF-1010; PF-1210; PF-1214; PF-1310; PF-1315; PF-1316; PE-1415;PF-1515; PF1717

2.Novel adjusting mechanism

3.Optimized structure

Impact crushers are ideal choice for crushing soft to middle-hard stones, this impact crusher features of reasonable structure, high capacity, safe performance, easy operation and maintenance. The most outstanding advantage of this impact crusher is that its finished particles are in good cubic shape and without any cranny.

As the secondary crushing equipment, impact crusher is more suitable for crushing all kinds of stones or minerals with compression strength not more than 320Mpa. It is widely used in highway, railway, airport, reservoir areas. It has high capacity, high performance, high crushing ratio, low cubic shape and pin shape. Impact crusher is equipped with one rotor on which there are four to eight hammer plates. When one sides of hammer plate is abraded, the other side can be used again. This kind of impact machine has the advantages of simple structure, high crushing ratio, low energy consumption, high output, light weight, cubical shape of final products . It has been widely used in industries such as chemical, cement, building materials, ceramics, refractory materials, such as the use of a variety of moderate hardness with finely crushed glass materials: limestone, clinker, slag, coke, coal, etc. Compared with hammer crusher, impact crusher has a larger reduction ratio, higher impact energy which can make full use of the entire rotor, more reliable working performance.Thus, impact crusher are warmly welcomed by users.

Before talk about the new economics of impact crusher's usage, it maybe well to briefly state the advantages of the impact crusher in the production of aggregate. Low invest cost has always been the first advantage of this equipment. For a given application this first cost may well be only a quarter as much as for compression type crusher installation. Second, a bigger reduction ratio can be achieved. Many installations are now producing specification stone from run-of-quarry feed in a single pass through a primary impact crusher. Third, impact units are capable of accepting larger feed sizes, with maximum feeding size up to 500mm. This larger feed size capability reduces material hang-up in the feed hopper and the need for secondary blasting or reducing oversize rock in the quarry before transporting it to the primary crusher. And fourth, impact crushing can produce a higher quality products which are in cubical shape and without the slivers or slabs, thus making it easier for quarry plant operators to meet the stringent specifications laid down by many customers. That is the biggest advantage compared to other crushers.