|

Shanghai Mekind Industrial Co., Limited

|

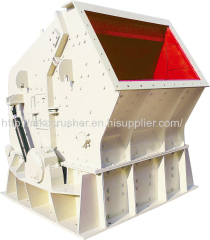

132kw Impact Crusher with Blow Bars for Rock Crushing

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Capacity arround 100~160tph

2. Two chambers or three chambers

3.Only manual can be selected

4. Discharged sizes are below 40m

Story of Impact Crusher PF1214:

This model impact crusher PF1214 is very popular in demestic and overseas market. It is usually used in the 80~100tph stone crushing plant to act as the secondary crusher. The primary crusher is equipped with jaw crusher PE600x900. Impact crusher is selected to crush soft or middle hardness materials. Sometimes, the raw material is hard, but our client want to use impact crusher to get cubical shaft of final products, normally, we equipe symons cone crusher or single cylinder hydraulic cone crusher before impact crusher to proceed a seondary crushing, which can reduce the abrasion of impact crusher.

Technical Data of Impact Crusher:

Model | PF1214 | PF-1214 |

Type of chamber | Two chamber | Three chamber |

Max feed Size (mm) | 350 | 350 |

Motor Power (kw) | 132 | 132 |

Capacity (t/h) | 110~160 | 100~160 |

Weight (t) | 18.5 | 19.2 |

Dimensions(mm) (LxWxH) | 2690x2740x2890 | 2690x2740x2890 |

Operating Principle:

Impact crusher crushes stones with impact force. When the stone or rock materials enter the crushing chambers, they are crushed due to the high-speed impact of the blow bars and are thrown to the impact plates on the rotor for second time crushing. Then the crushed stone or rock materials will be shot back to the blow bar again for the third crushing process. This process repeats until the materials are crushed to the required size and then discharged from the bottom of the impact crusher. The size and shape of the finished powder can be changed by adjusting the gap between the impact rack and rotor support. The machine employs self-weigh security device in impact crusher's back frame. When other objects enter the impact cavity, they will be forced out of the machine by the impact rack in the front and back of the impact crusher equipment.

Installation Instruction:

The machine is assembled by the factory and supplied in full sets. The users should closely examine the machine after getting the goods in case of unexpected damages to the machine during the transportation.

The instruction is only including the special installation instructions; others can accord to general instructions of machinery installation.

The crusher must be installed on the basis of strong steel reinforced concrete foundation base.

The height, depth, and area of the foundation should be according to the soil quality. The sizes for installation are marked in the foundation drawing. There should be enough space under the crusher bottom in case of installation of

transportation equipment and maintenance.

Vibration-absorbing material should be filled in the backlash between the machine and the foundation to release the vibration.

The machine could also be installed on steel frame.

The motor is installed on the right; it can be installed on the left, and the foundation base should be changed accordingly.

More Pictures about the Impact Crusher PF1214: