|

Shanghai Mekind Industrial Co., Limited

|

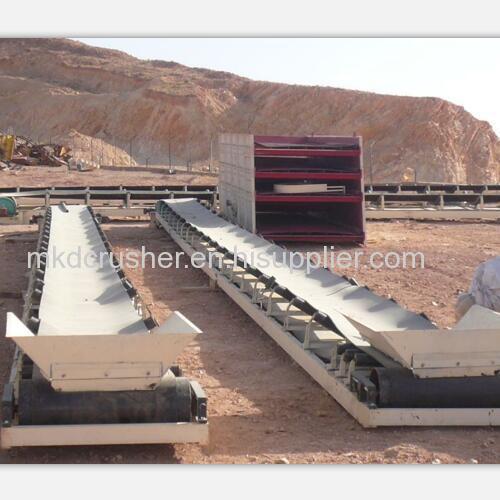

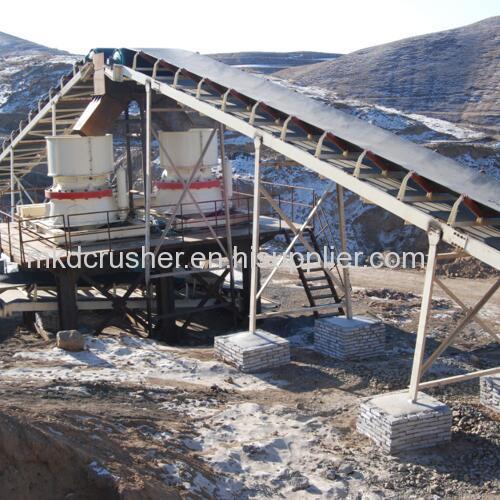

Stationary Canvas Belt Conveyor for Rock Crushing Plant

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The features of the conveyor produced by our company are with high capacity, simple structure, standard components, and easy to maintain

1. Usage:

The machine is primarily used to deliver materials or member units. The materials could be delivered by one conveyor or several combined conveyors according to the process requirements. The conveyors also could be combined into a level or gradient conveying system to satisfy various requirements of the production line.

The features of the conveyor produced by our company are with high capacity, simple structure and standard components. Moreover, they are easy to maintain.

2. Main technical Data:

Belt Width (mm) | Belt Length (m) | Power (kw) | Belt Speed (m/s) | Capacity (t/h) |

400 | ≤12 | 1.5 | 0.8~2.0 | 40~80 |

12-20 | 2.2 | |||

20-25 | 3 | |||

500 | ≤12 | 3 |

0.8~2.0 | 78~191 |

12-20 | 4 | |||

20-30 | 5.5 | |||

650 | ≤12 | 4 | 0.8~2.0 | 131~323 |

12-20 | 5.5 | |||

20-30 | 7.5 | |||

800 | ≤6 | 4 | 1.0~2.0 | 278~546 |

6-15 | 5.5 | |||

15-25 | 7.5 | |||

1000 | ≤10 | 5.5 | 1.0~2.0 | 435~853 |

10-20 | 7.5 | |||

20-25 | 11 | |||

1200 | ≤10 | 7.5 | 1.0~2.0 | 655~1284 |

10-20 | 11 | |||

20-25 | 15 |

Remarks:

1. The given capacity listed in this table is according to the macadam with delivering density 1.6/m2.

2. The setting angle should be smaller than 18°.

3. Our company could make out various designs of configuration according to the guests' special requirements.

3. Application and Maintenance:

3.1. The preparing work before starting.

3.1.1 Examine the lubricant condition of the bearing.

3.1.2 Examine all the fasteners.

3.1.3 Examine the conveyor belt. If it is worn out, it should be replaced at once. When the belt or the belt pulley is greasy, they should be erased at once.

3.1.4 Examine the protection parts. The dangerous factors should be eliminated at once.

3.2. Starting:

3.2.1 The crusher must be started under the no-load condition.

3.2.2 There should be an alarm or a signal before starting.

3.2.3 If abnormal movement occurs after starting, the process should be paused at once. The machine can be restarted only after finding out and eliminating the abnormal condition.

3.3. Application:

3.3.1 The feeding materials should be put onto the conveyor after it operates normally.

3.3.2 The materials should be delivered evenly.

3.3.3 Stop adding materials onto the belt before stopping the conveyor. The electric motor shouldn't be powered off until all the material is emerged from conveyor belt.

3.3.4 Fasten the nuts after the machine is in service for some time to avoid damages caused by the loose nuts.

3.4. Lubrication:

3.4.1 Examine regularly whether the lubrication of the friction surface is in good condition to ensure the normal operation of the crusher and the prolongation of the operating time.

3.4.2 The type of the grease added into the crusher depends on different sites, temperature and some other conditions. Usually calcium base grease, sodium base grease or calcium-sodium base grease are applicable.

4. Security:

4.1 The operators would operate the machine only after learning the safe operation rules.

4.2 Any adjustments, cleaning or repairs are forbidden when the belt is operating.

4.3 It's forbidden to remove the stones into or out of the belt directly with your hands when the belt is operating.

4.4 The electrical equipments should be grounded. The electric wires should be insulated and put into reptile skin.